The report"Sodium hydrosulfiteManufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue"by IMARC Group presents a comprehensive guide to establish a sodium hydrosulfitemanufacturing plant. The report offers an in-depth market analysis and information on unit operations, raw materials, utility and infrastructure requirements, technology and machinery requirements, manpower requirements, packaging and transportation requirements. Additionally, the report details the project economics, including capital investment, project funding, operational expenses, income and expenditure projections, variable and fixed costs, direct and indirect costs, expected ROI, net present value, profit and loss account, and financial analysis.

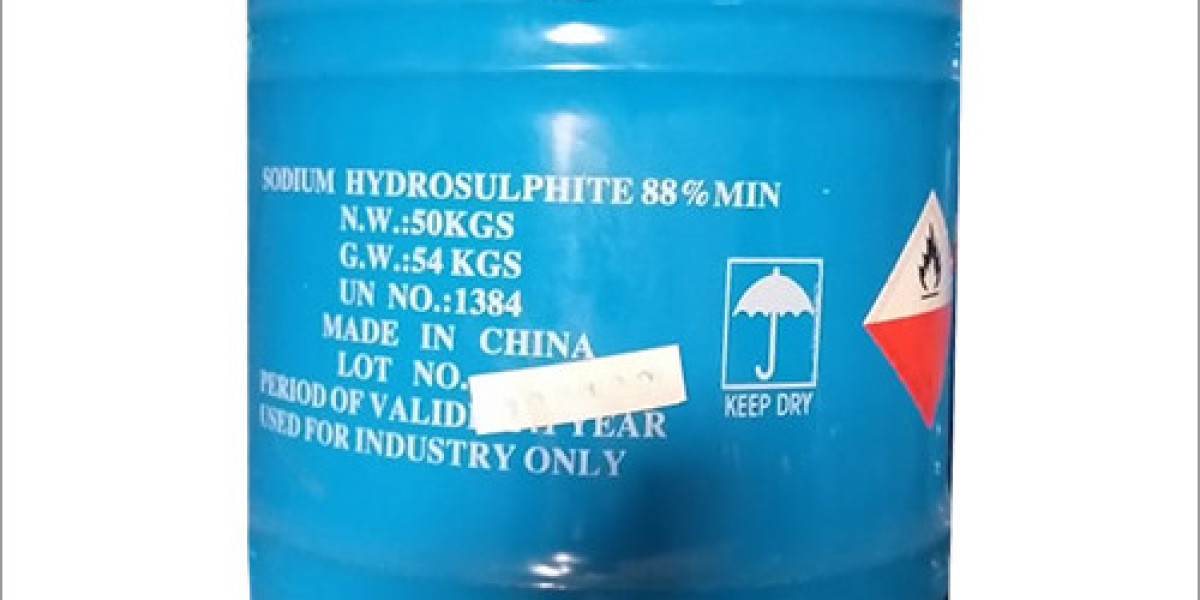

Sodium hydrosulfite, also referred to as sodium dithionite, is a potent reducing agent that has garnered significant attention due to its wide array of applications. This inorganic compound, represented by the chemical formula Na2S2O4, comprises sodium, sulfur, and oxygen atoms. Encountered commonly as a white crystalline powder or as a water-based solution, sodium hydrosulfite plays a pivotal role in various industries.One primary application of sodium hydrosulfite lies in the textile industry, where it serves as a bleaching agent for fabrics. Its remarkable ability to remove colorants and stains from textiles makes it an indispensable component in producing vibrant and clean-looking garments.Moreover, the pulp and paper industry extensively utilizes sodium hydrosulfite as a deinking agent to eliminate ink from recycled paper, contributing to the production of high-quality paper products.

he sodium hydrosulfite market is currently witnessing substantial growth, primarily due to various market drivers and emerging trends. A significant factor contributing to this growth is the escalating demand from the textile industry. Sodium hydrosulfite plays a crucial role as a bleaching agent in textile manufacturing, facilitating the removal of colorants and stains from fabrics. Given the rapid expansion of the global textile industry and the increasing preference for high-quality, vibrant textiles, the demand for sodium hydrosulfite is expected to surge further.Another driving force behind the market's growth is the pulp and paper industry, which extensively uses sodium hydrosulfite as a deinking agent during paper recycling processes. This application aids in the removal of ink from recycled paper, aligning with the industry's heightened focus on sustainability and recycling. As the demand for recycled paper rises in response to environmental concerns, the need for deinking agents like sodium hydrosulfite is experiencing an upward trajectory.Furthermore, sodium hydrosulfite finds wide-ranging applications in diverse chemical processes, particularly in water treatment and wastewater management. It serves as an effective reducing agent, facilitating the elimination of impurities and pollutants from water sources. Given the increasing stringency of environmental regulations and growing concerns about water pollution, the demand for efficient water treatment solutions, including sodium hydrosulfite, is witnessing a notable surge.

Report Coverage:

Market Segments:The following analysis is provided in the report:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Outlook

Detailed Process Flow:The project report offers detailed information about the process flow and the various unit operations for setting up a sodium hydrosulfitemanufacturing plant.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

Project Details, Key Requirements and Costs Involved:The report covers the below aspects:

- Land, Location and Site Development

- Plant Layout Details

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

Project Economics:The report provides the below information about the project economics:

- Capital Investments

- Operating Costs

- Expenditure and Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

Key Questions Addressed in the Report onSodium HydrosulfiteManufacturing Plant Project:

- How has the sodium hydrosulfite market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global sodium hydrosulfite market?

- What is the regional breakup of the global sodium hydrosulfite market?

- What are the price trends of various feedstocks in the sodium hydrosulfite industry?

- What is the structure of the sodium hydrosulfite industry and who are the key players?

- What are the various unit operations involved in a sodium hydrosulfite manufacturing plant?

- What is the total size of land required for setting up a sodium hydrosulfite manufacturing plant?

- What is the layout of a sodium hydrosulfite manufacturing plant?

- What are the machinery requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the raw material requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the packaging requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the transportation requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the utility requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the human resource requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the infrastructure costs for setting up a sodium hydrosulfite manufacturing plant?

- What are the capital costs for setting up a sodium hydrosulfite manufacturing plant?

- What are the operating costs for setting up a sodium hydrosulfite manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for a sodium hydrosulfite manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up a sodium hydrosulfite manufacturing plant?

- What are the key success and risk factors in the sodium hydrosulfite industry?

- What are the key regulatory procedures and requirements for setting up a sodium hydrosulfite manufacturing plant?

- What are the key certifications required for setting up a sodium hydrosulfite manufacturing plant?