The report "Amyl Acetate Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" by IMARC Group presents a comprehensive guide to establish a Amyl Acetate manufacturing plant. The report offers an in-depth market analysis and information on unit operations, raw materials, utility and infrastructure requirements, technology and machinery requirements, manpower requirements, packaging and transportation requirements. Additionally, the report details the project economics, including capital investment, project funding, operational expenses, income and expenditure projections, variable and fixed costs, direct and indirect costs, expected ROI, net present value, profit and loss account, and financial analysis.

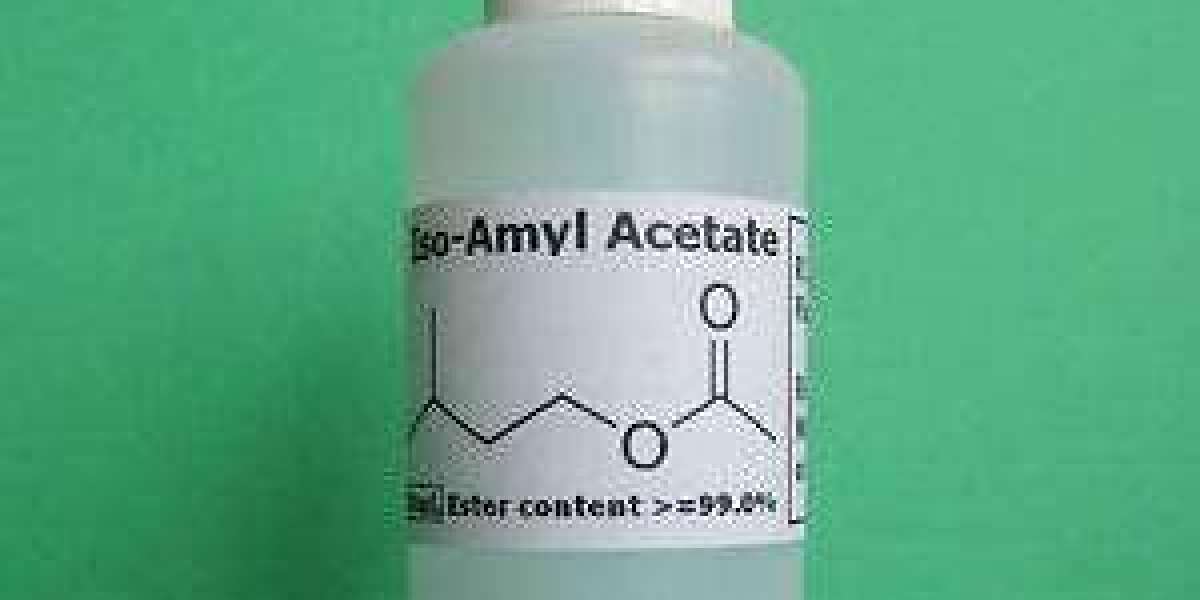

Amyl acetate, also referred to as pentyl acetate, emerges as a product of the reaction between amyl alcohol and acetic acid. Whether produced naturally or synthetically, this compound offers an economical option with remarkable purity and a delightful fruity fragrance. Notably, it possesses outstanding solvency abilities, rendering it indispensable for dispersing resins and various additives. Moreover, amyl acetate greatly enriches the sensory experience for consumers. Its widespread application in household cleaning products, air fresheners, and deodorizers has sparked a global increase in demand for this adaptable and highly desired chemical.

Request Sample:https://www.imarcgroup.com/amyl-acetate-manufacturing-plant-project-report/requestsample

The market for amyl acetate is experiencing significant growth, primarily due to its wide range of applications as a solvent and flavor enhancer in various food products. Additionally, its popularity in crafting fragrances, perfumes, lotions, creams, and scented items has played a crucial role in expanding the market, enhancing consumers' olfactory experiences. Moreover, the manufacturing sector's increasing demand for amyl acetate in coatings, adhesives, and paints has created lucrative opportunities for industry investors.Furthermore, amyl acetate's effectiveness as an industrial degreaser and cleaning solution, facilitating the breakdown and elimination of grease, oil, and dirt from surfaces, has further driven market expansion. The rising consumption of candies, beverages, and desserts has also contributed to the positive outlook for amyl acetate, as its demand in their production continues to grow.In response to the growing emphasis on environmental sustainability, key industry players are proactively introducing bio-based amyl acetate, which is playing a vital role in driving market growth. The adoption of eco-friendly practices across various industries has made bio-based alternatives more appealing to businesses and consumers alike. This focus on sustainability aligns with the increasing importance placed on environmental concerns, making it an attractive proposition for all stakeholders involved in the amyl acetate market.

Report Coverage:

Market Segments:The following analysis is provided in the report:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Outlook

Detailed Process Flow:The project report offers detailed information about the process flow and the various unit operations for setting up a amyl acetate manufacturing plant.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

Project Details, Key Requirements and Costs Involved:The report covers the below aspects:

- Land, Location and Site Development

- Plant Layout Details

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

Project Economics:The report provides the below information about the project economics:

- Capital Investments

- Operating Costs

- Expenditure and Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

Key Questions Addressed in the Report onAmyl AcetateManufacturing Plant Project:

- How has the amyl acetate market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global amyl acetate market?

- What is the regional breakup of the global amyl acetate market?

- What are the price trends of various feedstocks in the amyl acetate industry?

- What is the structure of the amyl acetate industry and who are the key players?

- What are the various unit operations involved in an amyl acetate manufacturing plant?

- What is the total size of land required for setting up an amyl acetate manufacturing plant?

- What is the layout of an amyl acetate manufacturing plant?

- What are the machinery requirements for setting up an amyl acetate manufacturing plant?

- What are the raw material requirements for setting up an amyl acetate manufacturing plant?

- What are the packaging requirements for setting up an amyl acetate manufacturing plant?

- What are the transportation requirements for setting up an amyl acetate manufacturing plant?

- What are the utility requirements for setting up an amyl acetate manufacturing plant?

- What are the human resource requirements for setting up an amyl acetate manufacturing plant?

- What are the infrastructure costs for setting up an amyl acetate manufacturing plant?

- What are the capital costs for setting up an amyl acetate manufacturing plant?

- What are the operating costs for setting up an amyl acetate manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for an amyl acetate manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up an amyl acetate manufacturing plant?

- What are the key success and risk factors in the amyl acetate industry?

- What are the key regulatory procedures and requirements for setting up an amyl acetate manufacturing plant?

- What are the key certifications required for setting up an amyl acetate manufacturing plant?